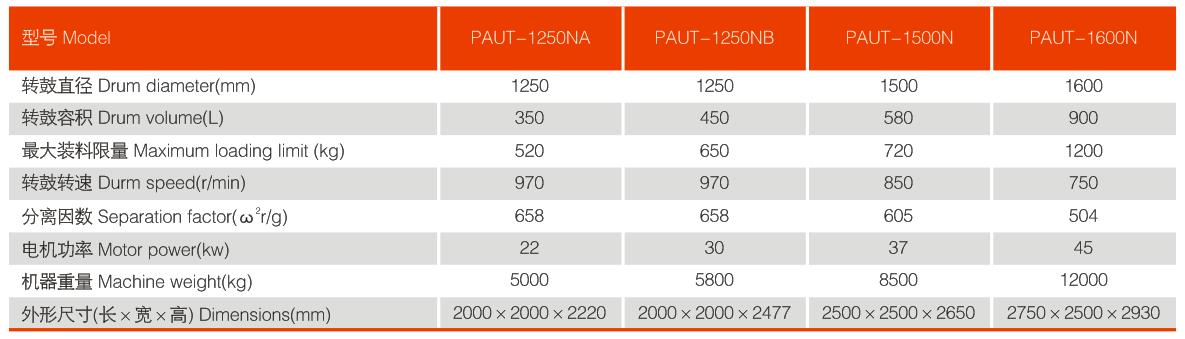

| Availability: | |

|---|---|

| Quantity: | |

standard manufacturing form

■Structure: The housing is equipped with a feed pipe, a washing pipe, a sight glass, an exhaust port, a manhole, and a lighting hole.Closed structure, bowl, shell and lid are all made of stainless steel.The machine base is made of carbon steel.The surface is coated with stainless steel.The inner and outer surfaces of the drum, the shell, and the surfaces of exposed parts inside and outside the machine are all polished and mirror-finished.

■All fasteners are made of stainless steel.

■Adopt PLC program control.

■Drive and braking: hydraulic motor + frequency converter + energy consumption braking

■Pneumatic (hydraulic) action system

■PAUT adopts flat plate structure and liquid shock absorber.

Purpose and characteristics

■Adopts PLC control, program setting, unattended automatic operation, and full monitoring of feeding, primary filtration, washing, fine filtration, and discharging.

■Variable frequency speed regulation, smooth start, and adjustable separation coefficient.

■The motor adopts top-mounted direct-coupling type, which avoids friction and dust caused by driving.

■High productivity, high output, improved production efficiency

■Energy-consuming braking, non-contact braking method, no friction, no dust pollution

■Fully enclosed structure.Seals are made of silicone rubber or fluoroelastomer.The centrifuge chamber is equipped with nitrogen protection to meet sealing and explosion-proof requirements.

■Reasonable structural design.The CIP cleaning system (spray system) ensures cleanliness requirements and complies with GMP standards.

■Using pneumatic (hydraulic) action system, clean and hygienic.

■Electromechanical material control.

■A gas-assisted scraper is optional to ensure that there is no cake left in the drum after unloading.

■Safety protection: speed detection, over-vibration protection, cover removal protection, motor overload and overheating protection, mechanical and electric dual control of scraper turning and lifting, and linkage locking of scraper and drum.

Optional

■Clean the spray system

■Nitrogen protection system

■RF admittance material process control

■PLC program control

■Hydraulic action system

■Gas assisted scraper

■No basic form (equipped with vibration isolation chassis + shock absorber).

■Stainless steel compatible (SUS304, 321, 316L, 904L, duplex stainless steel, titanium, etc.)

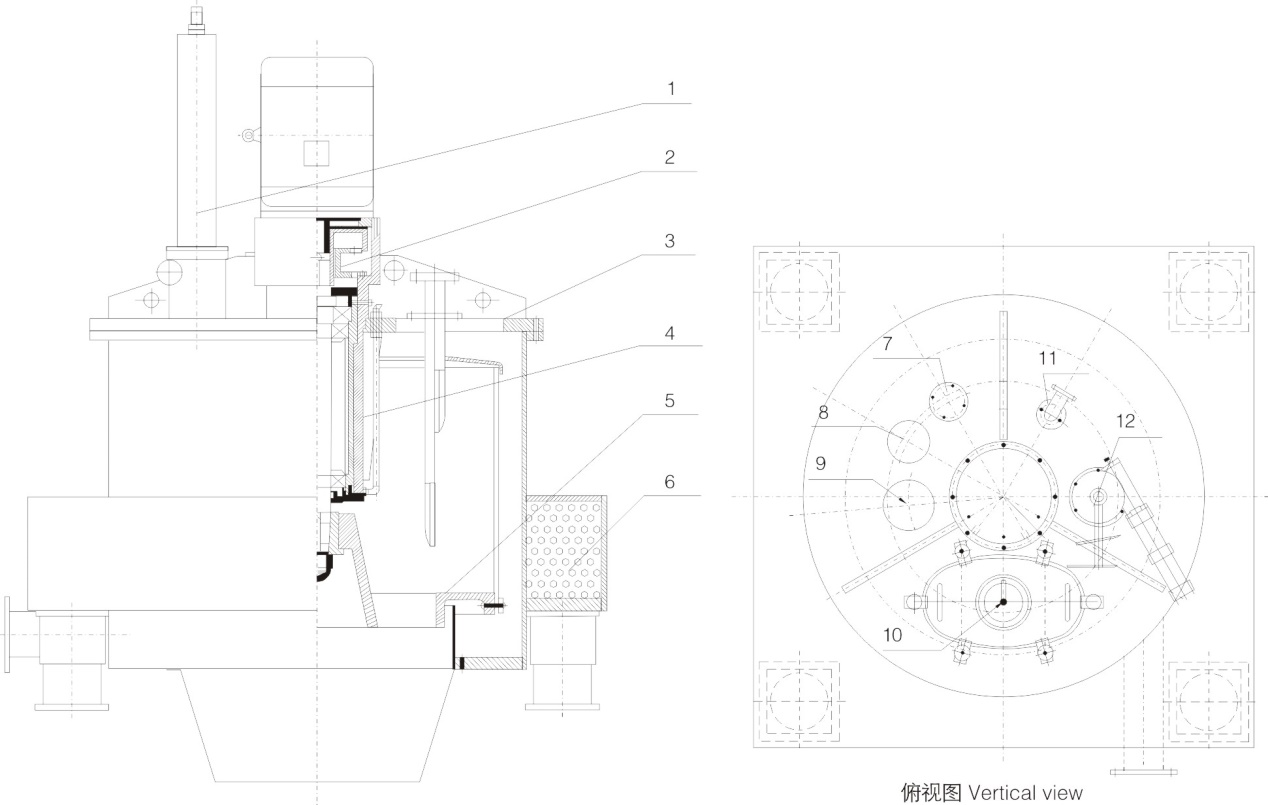

1. Scraper mechanism

2. Transmission components

3. Top

4. Bearing parts

5. Drum parts

6. Frame components

7.Controller material layer

8. Bed viewing hole

9. Feeding port

10. Manual operation

11. Washing pipe

12. Blade hole